Visit our website on your desktop for more project info.

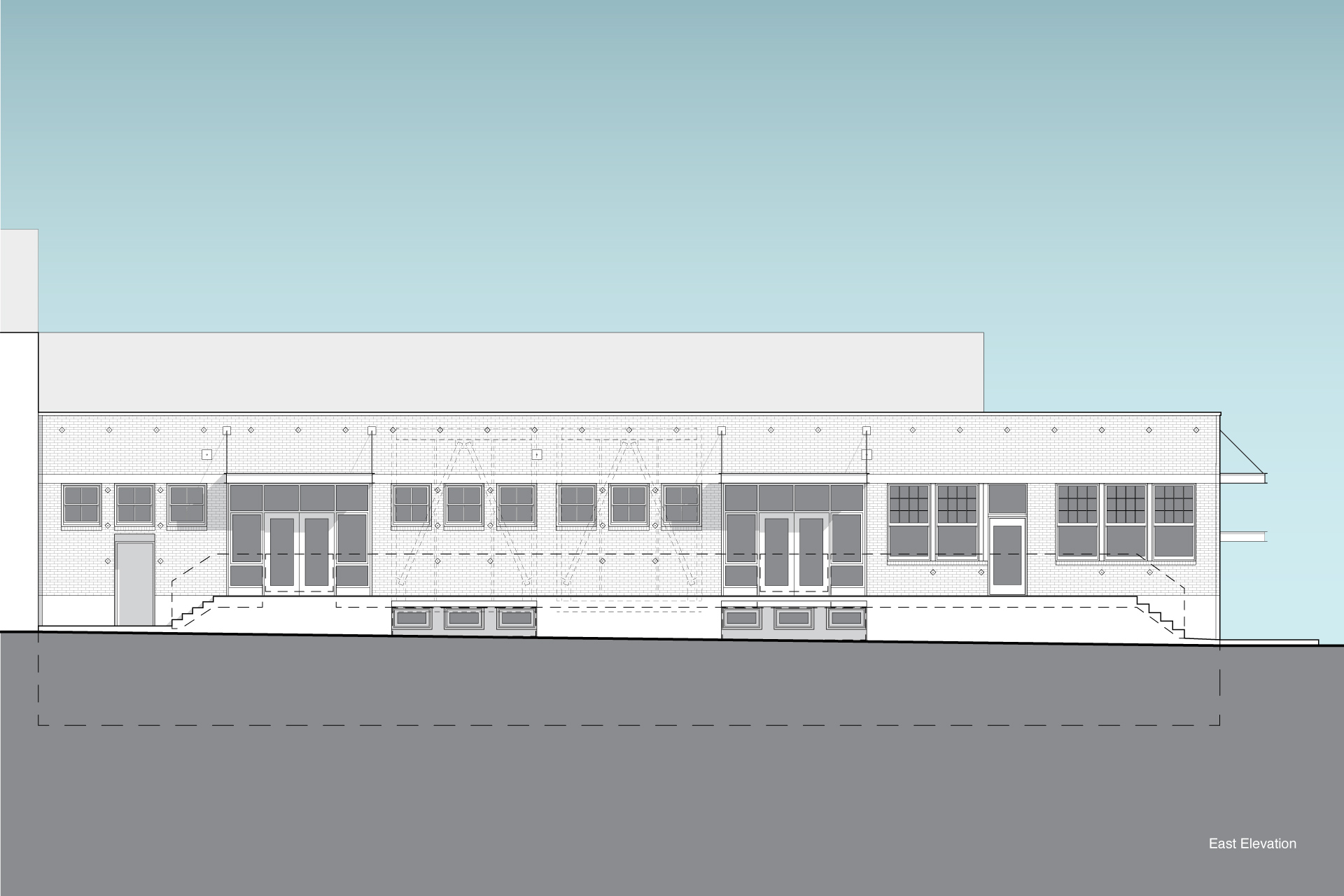

The Central Eastside Industrial District of Portland features several hundred old warehouses. Many of the buildings are brick and timber structures–a desirable palette of rich materials too expensive to build with today. As this neighborhood grows away from wholesale distribution to retail and office functions, building owners want to renovate rather than tear down. These buildings need a warehouse renovation, and that is exactly what we did with this old building.

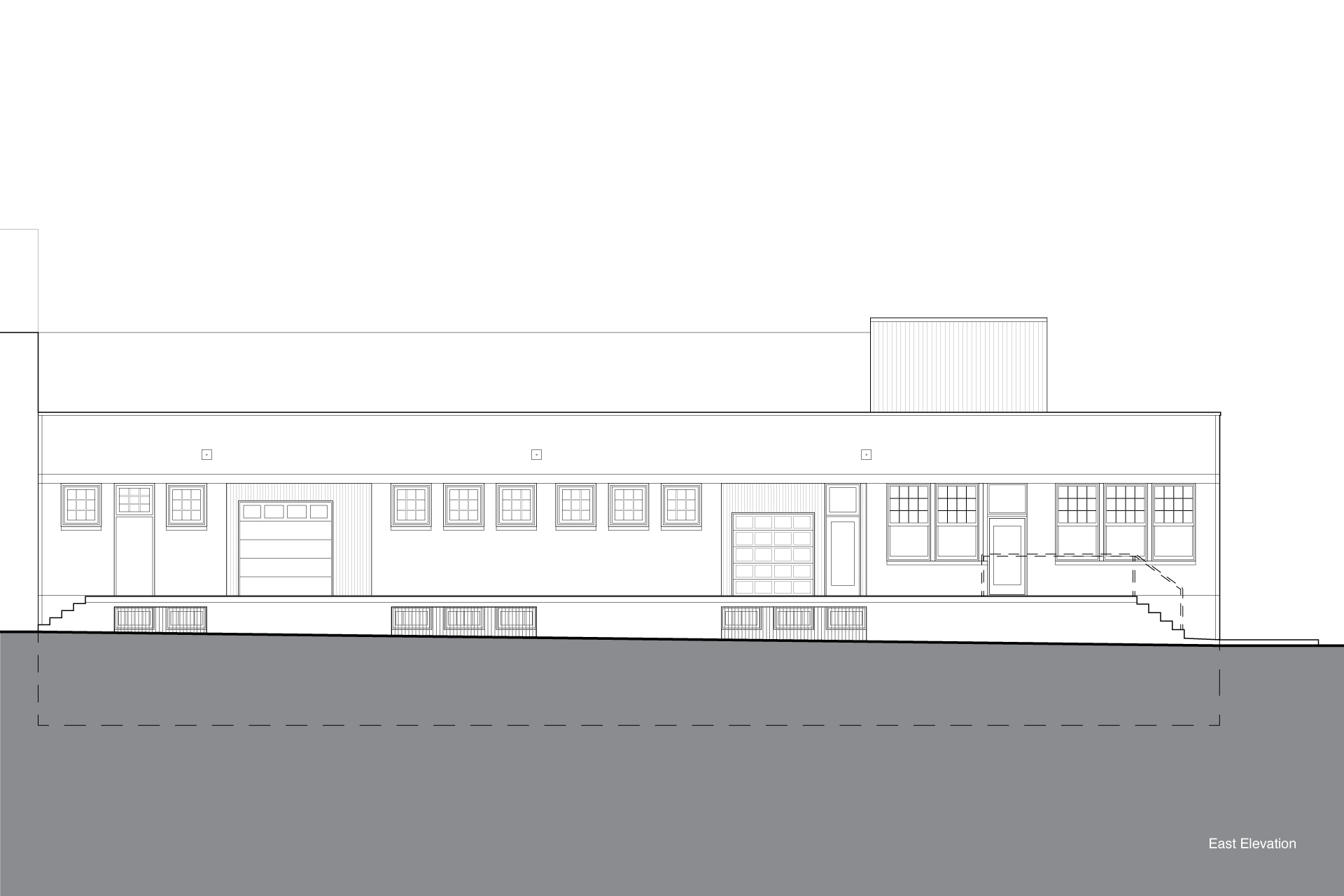

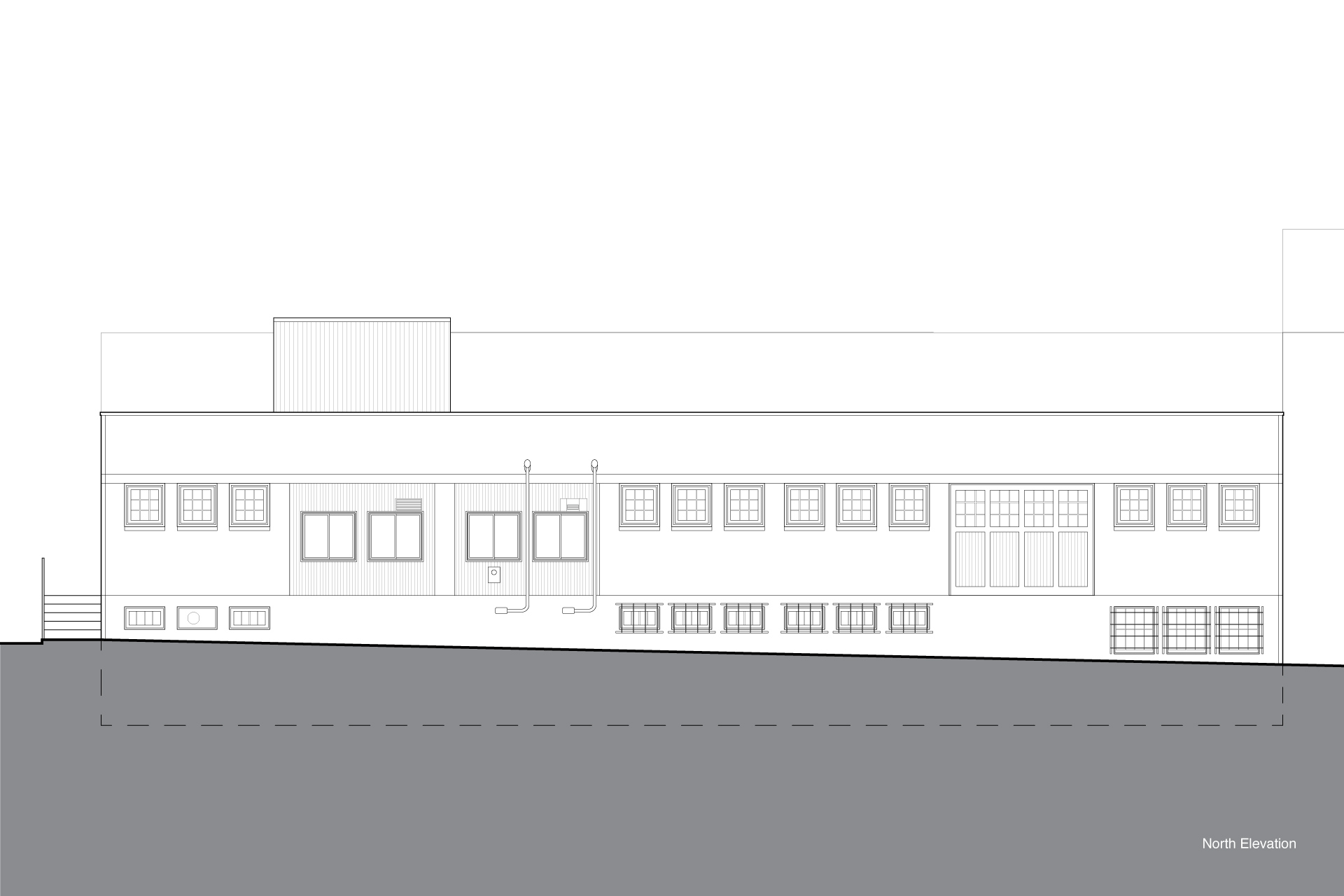

The owners of the Taylor Building anticipated leasing the upgraded 1921 historic structure to a variety of small businesses. Leasable spaces ranged from 1,000 sf up to an entire floor at 10,000 sf.

While it would have been great to keep the old platform freight elevator with its horizontally split double door, it did not provide easy access to the building. Instead, we suggested a new lobby at the northeast corner where the sidewalk dropped to its lowest point. This allowed an accessible entry with an elevator for all the tenants. The original loading dock elevator remained on the east side for walkup entries.

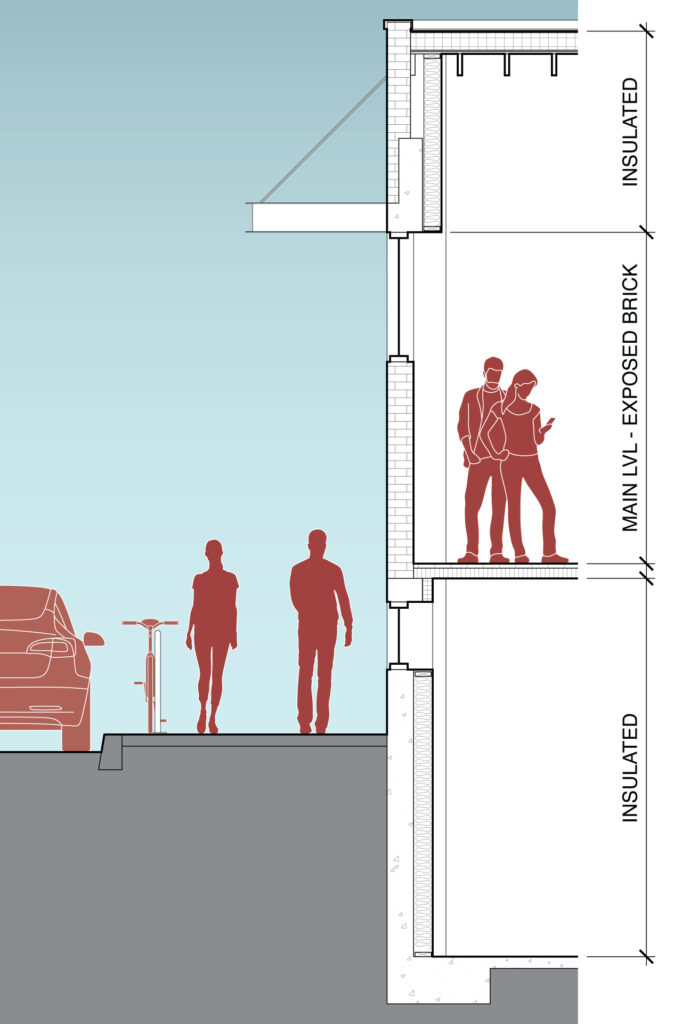

How do we preserve the historic exposed brick and timber vibe when the energy code requires we cover it up?

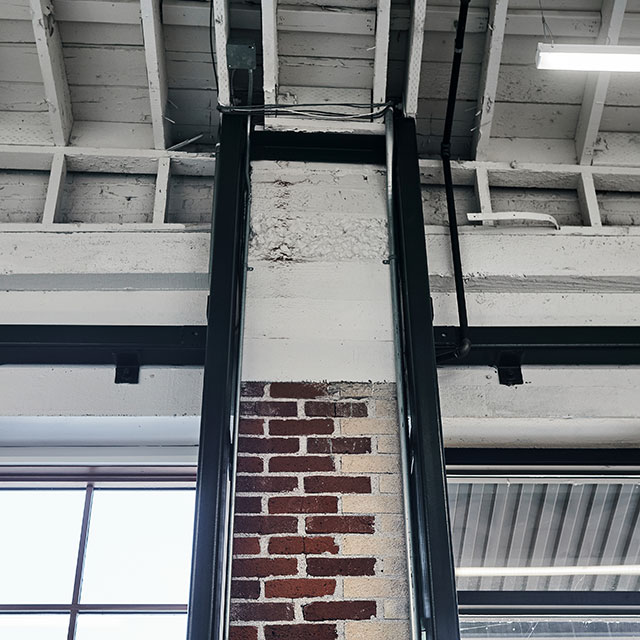

The charm of this building is in its historic industrial materials. However, to satisfy the energy code, the building needs insulation; it had none at all. We couldn’t cover the exterior since this building sits at the property line. And we didn’t want to reclad it anyway; we liked the brick.

We modeled the building for energy to assess how much wall area we could keep exposed. The highest priority was balancing the need to insulate with the desire to keep the industrial vibe. In the end, we decided the most impactful area to preserve the exposed brick was at the main level entry and lobby. We kept the ceiling as exposed deck by insulating on top of the roof.

Structural engineers call these old buildings URM’s: “Un-Reinforced Masonry” buildings.

Although Portland is in a high seismic area, we didn’t recognize the need to reinforce buildings appropriately until the 1990’s. And in 2004, it became a requirement for owners to seismically upgrade their buildings as they renovated them.

For this warehouse renovation, we created steel frames on each exterior wall to brace the building without covering up the brick. At the old timber beam and column intersections, brackets, plates and holddowns stitch the old framing together with modern reinforcements. Though seemingly perilous-looking, the timbers with these reinforcements do the job, extending the life of this already 100-year old building.

A cool detail we discovered about the old building during the warehouse renovation was the blocks between the beams at the roof. Apparently, these were placeholders for a future expansion of the building. The blocks could hold timber columns to support new upper floors.

Timbers removed during demolition became stair treads in the new lobby. Old nail holes and the scars of 100 years of heavy duty performance add to the industrial vibe of the warehouse renovation.